Each one of our regulators is specifically engineered to fit your needs!

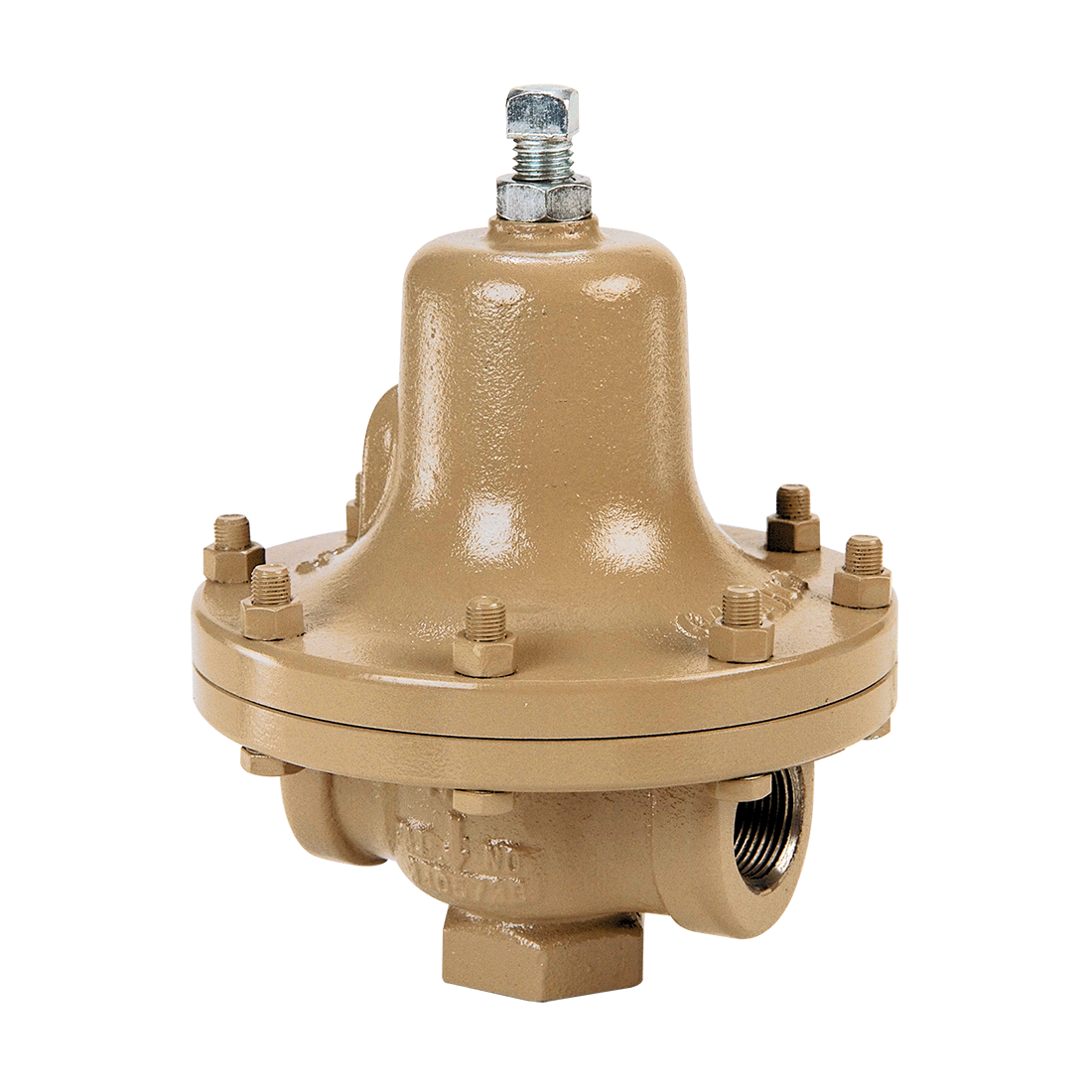

Our Top Selling Back Pressure Regulators

What is a back pressure regulator?

A back pressure regulator is a control device designed to maintain a set upstream pressure by relieving excess pressure in a system. These regulators are essential in applications where it is necessary to manage pressure build-up upstream of the regulator, ensuring system protection, maintaining efficiency, and enhancing safety. Below are four categories that provide a deeper understanding of back pressure regulators:

FUNCTION AND PURPOSE:

Back pressure regulators are designed to maintain a specified upstream pressure by releasing excess pressure once it exceeds the setpoint. This is vital in systems where pressure build-up can cause inefficiency or damage, such as in gas distribution networks, chemical processing plants, and fuel supply systems. By regulating pressure, these devices prevent over-pressurization, protect equipment, and ensure smooth operation of upstream components.

OPERATION:

Back pressure regulators function by sensing the pressure upstream of the regulator. When the upstream pressure exceeds the desired setpoint, the regulator opens, allowing fluid to flow through and relieve excess pressure. Once the pressure drops below the setpoint, the regulator closes, maintaining a stable upstream pressure. This dynamic process allows for precise control of system pressure, ensuring consistency and reliability in various operating conditions.

APPLICATIONS:

Back pressure regulators are widely used across numerous industries. In the oil and gas industry, they help manage the pressure in pipelines and storage tanks. In chemical and pharmaceutical processes, they ensure consistent pressure for precise dosing and reaction control. Back pressure regulators are also employed in fuel supply systems, ensuring the safe operation of engines and turbines by preventing over-pressurization in fuel lines.

TYPES AND VARIETIES:

Back pressure regulators are available in various designs, tailored to different application needs. Common types include spring-loaded regulators, pilot-operated regulators, and dome-loaded regulators. Spring-loaded regulators are simple and cost-effective for general applications. Pilot-operated regulators offer higher accuracy and are suitable for systems with varying flow rates. Dome-loaded regulators provide fine pressure control and stability, ideal for critical applications where precise pressure management is essential.

SEE HOW A BACK PRESSURE REGULATOR WORKS!

Selecting the right product for your application is our top priority! Complete the form below and our team will be happy to size and select the right product for your industrial application!