Each one of our valves is specifically engineered to fit your needs!

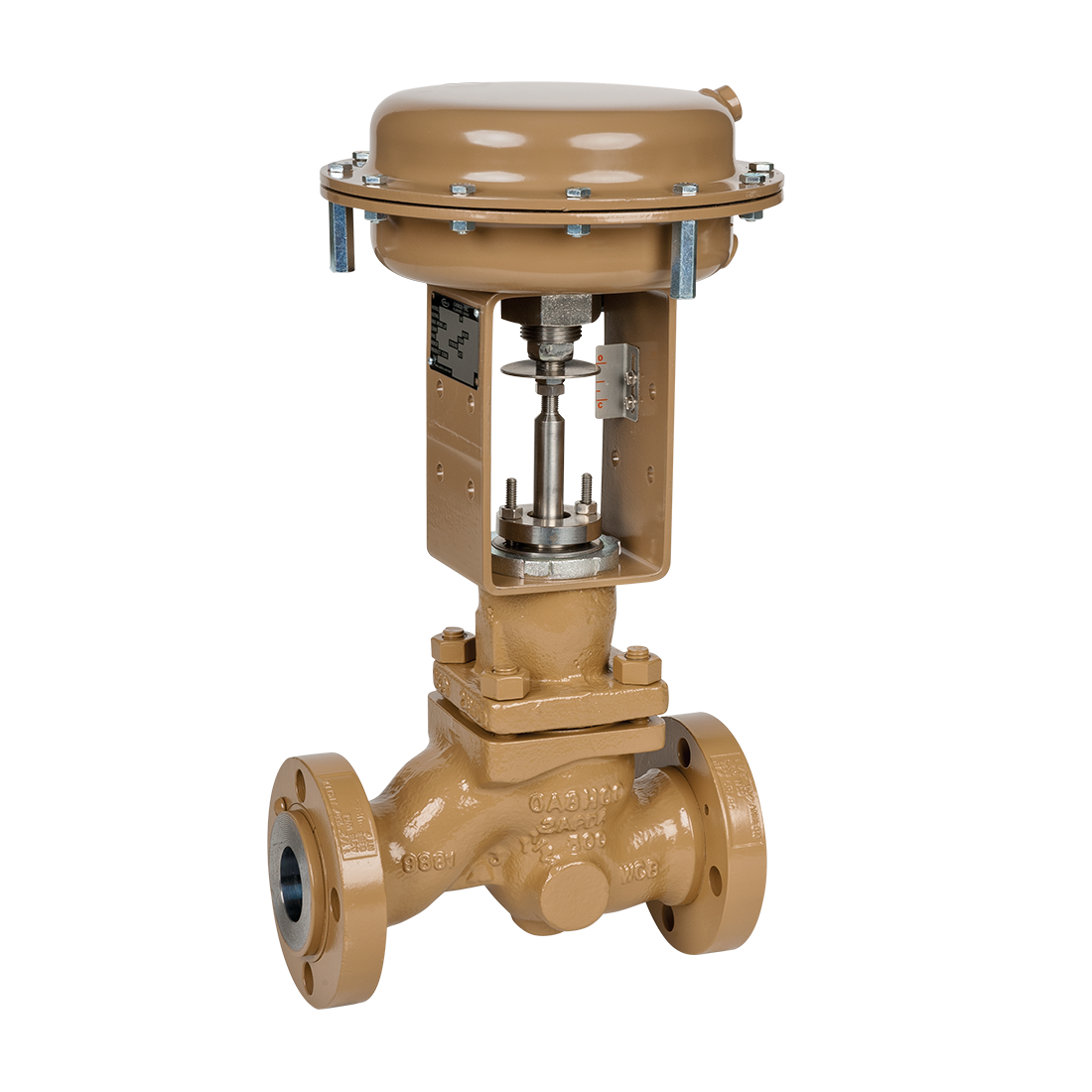

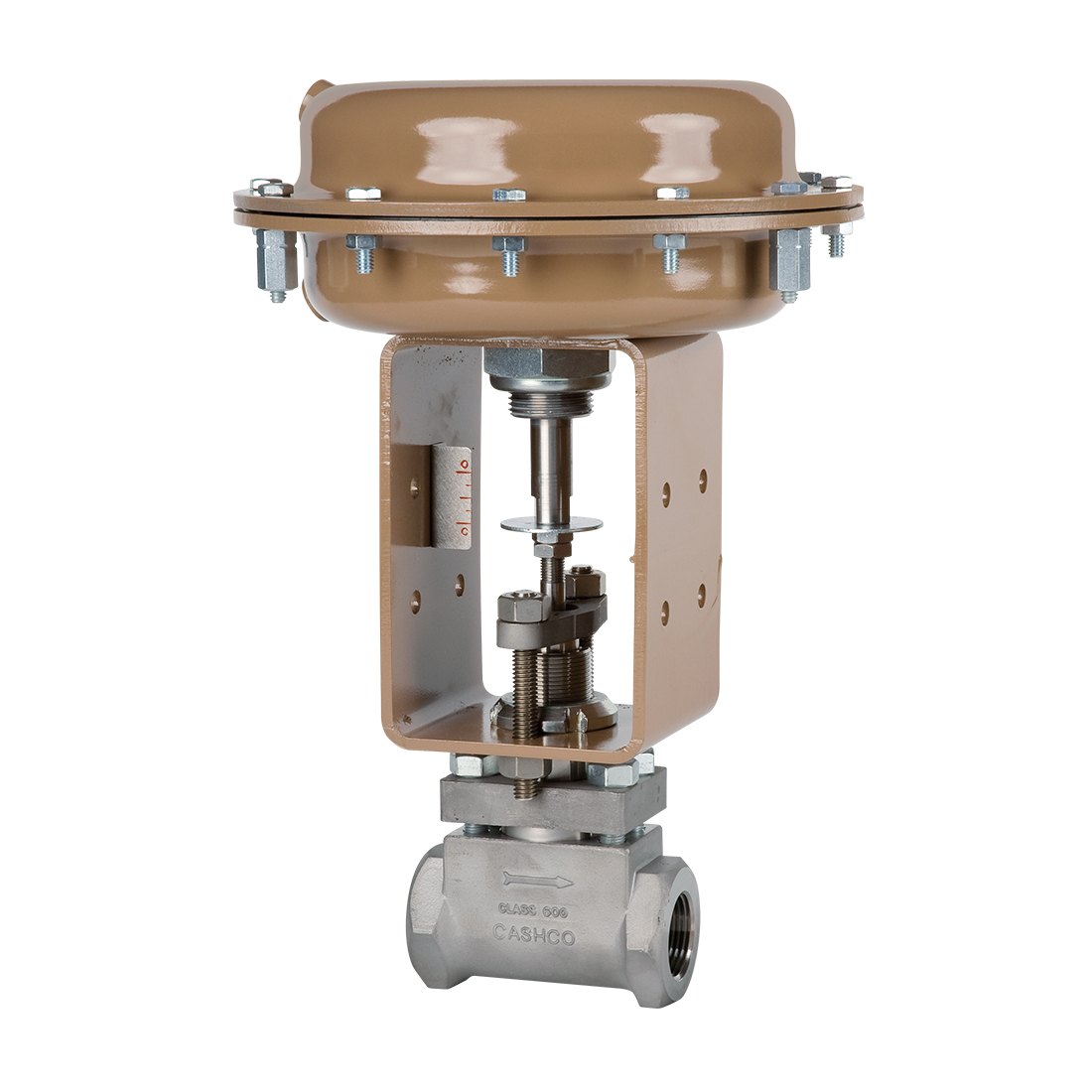

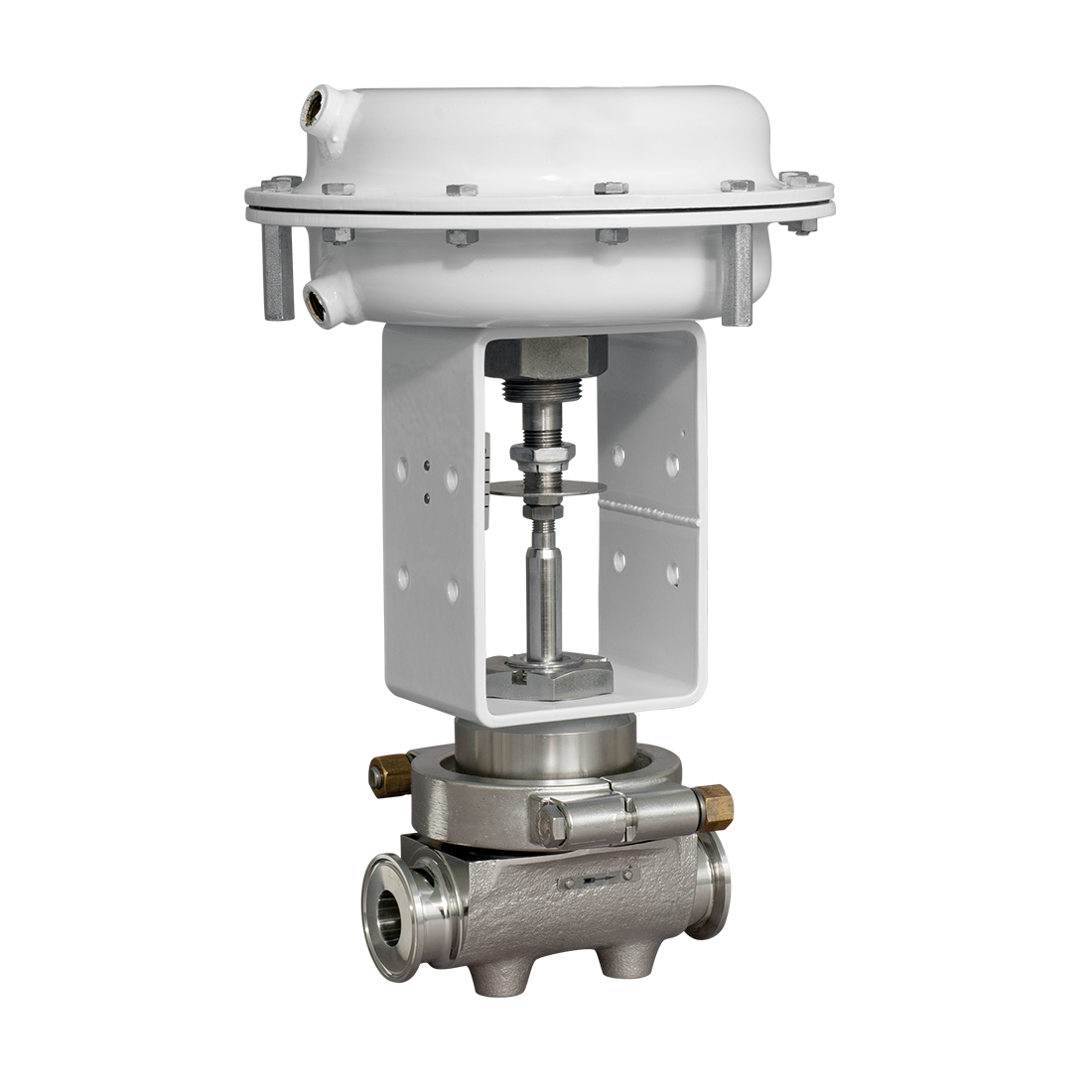

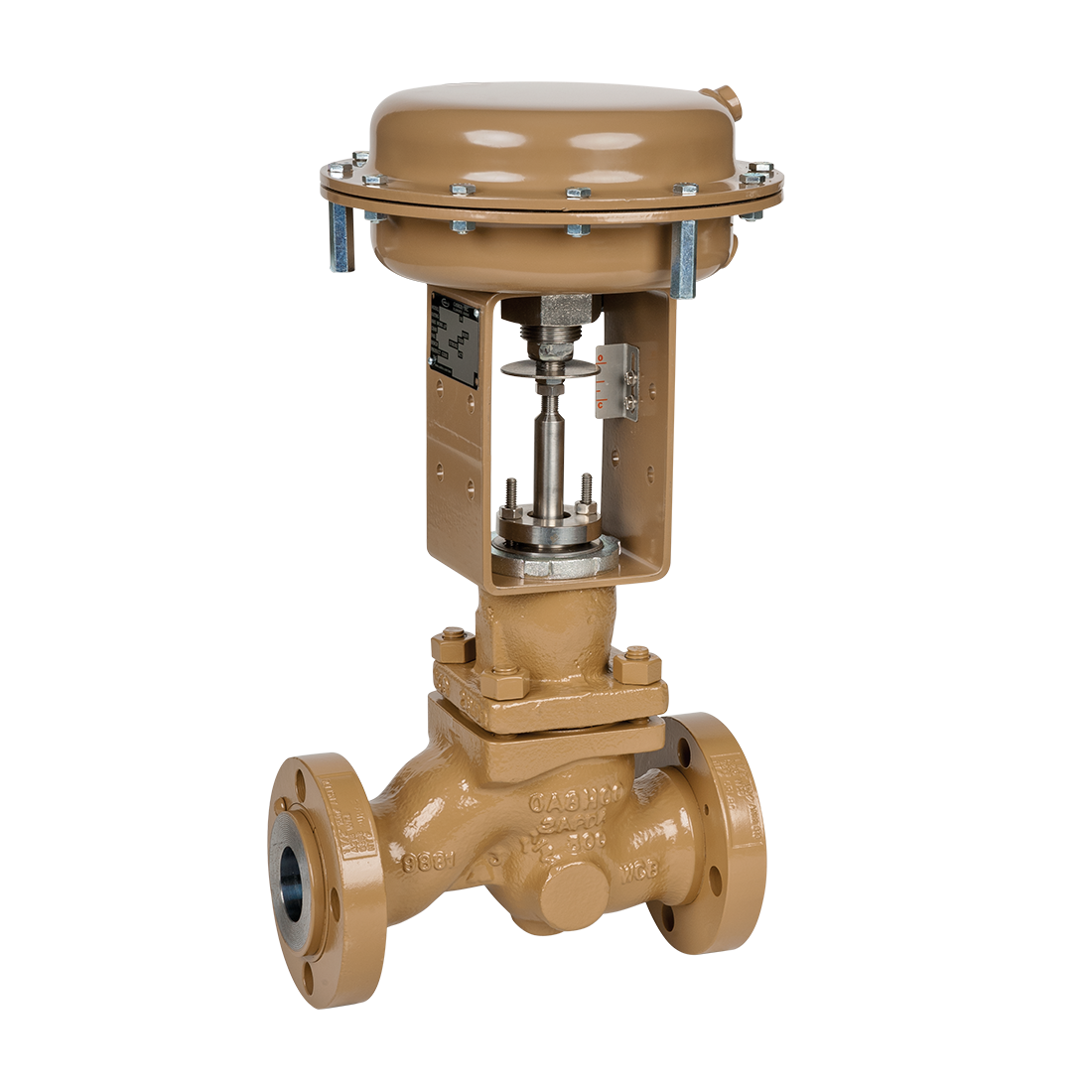

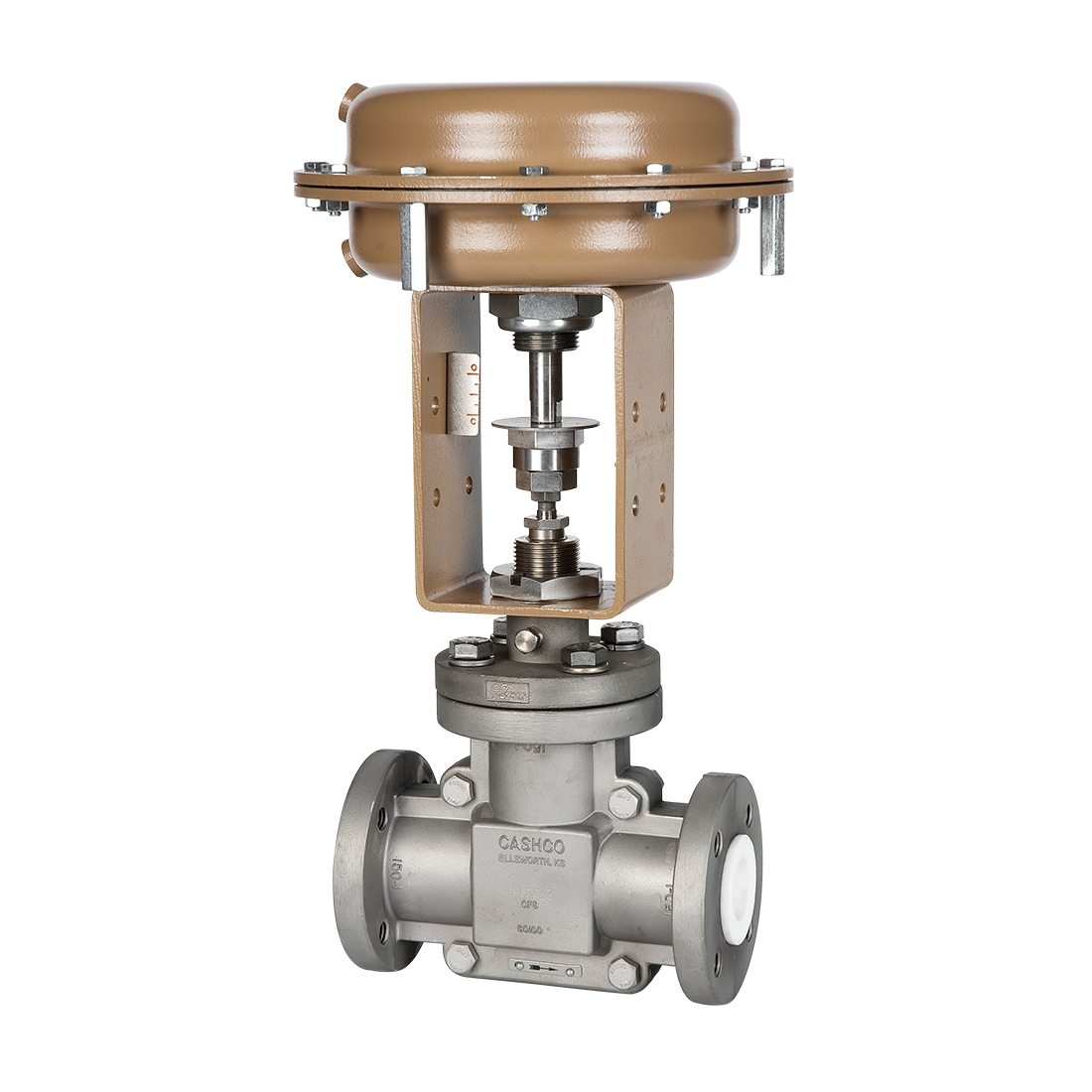

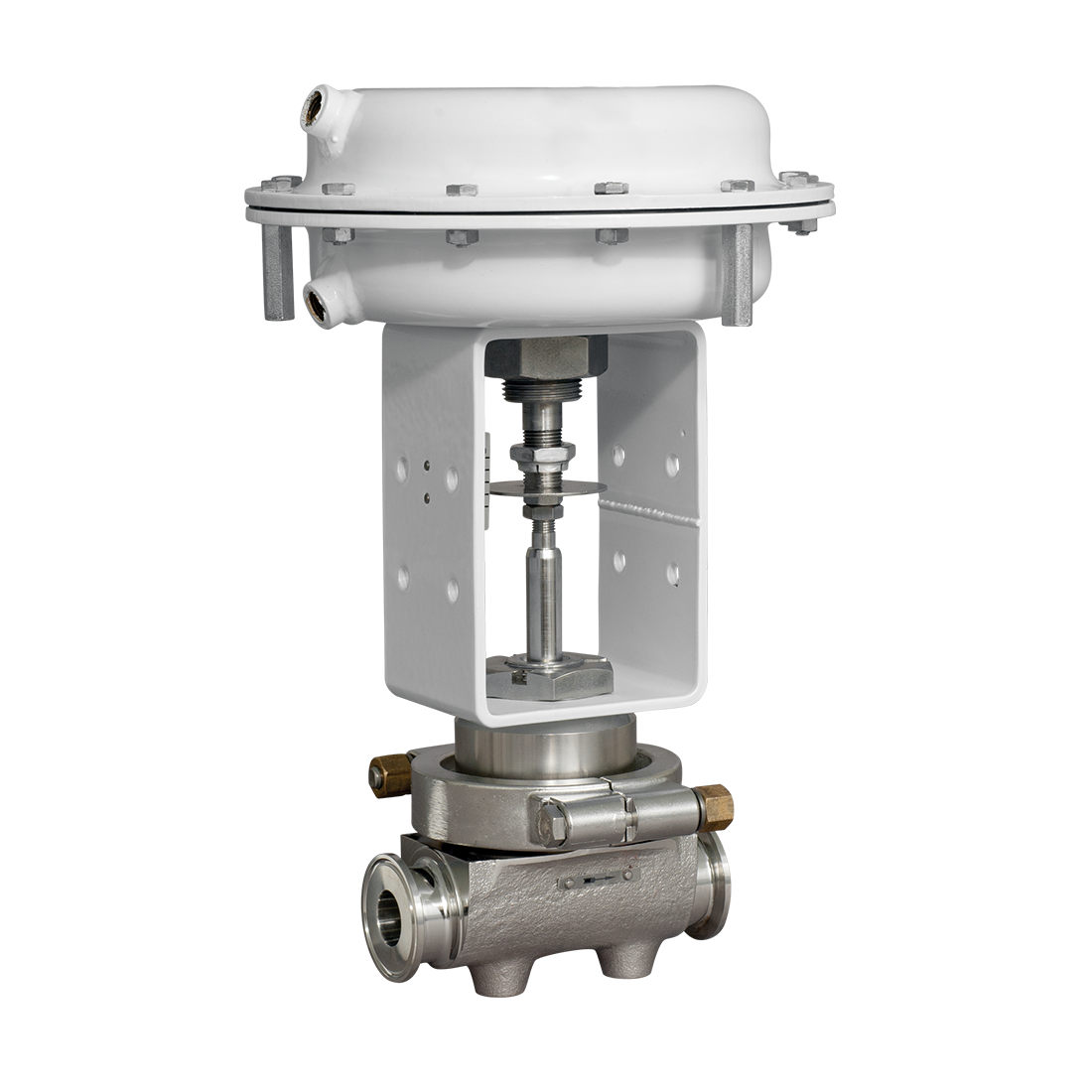

Our Top Selling Control Valves

What is a control valve?

A control valve is a device used to regulate the flow, pressure, temperature, or level of fluids in a system, ensuring precise control to meet specific process requirements. Control valves are critical components in various industrial applications, enabling efficient operation and maintaining safety by dynamically adjusting fluid parameters to desired levels. Here are four categories to explain control valves:

FUNCTION AND PURPOSE:

Control valves are designed to modulate fluid flow by varying the size of the flow passage in response to signals from a control system. This functionality ensures that critical process variables such as pressure, flow rate, and temperature remain within specified limits. By regulating these variables, control valves protect equipment, optimize system performance, and maintain the stability of operations in applications such as oil refining, power generation, and chemical manufacturing.

OPERATION:

Control valves operate through a combination of actuators, sensors, and internal mechanisms. The valve receives an input signal, typically pneumatic, hydraulic, or electric, from a control system. This signal directs the actuator to adjust the position of the valve to control the flow rate of the fluid passing through. This precise modulation ensures that the system achieves the desired output parameters, even under varying conditions, making control valves indispensable for maintaining consistent process performance.

APPLICATIONS:

Control valves are utilized in various industries. In the oil and gas sector, they regulate the flow of hydrocarbons during production and refining processes. Power plants rely on them to manage steam flow in turbines and heat exchangers. The pharmaceutical and chemical industries use control valves to ensure accurate mixing and reaction conditions. In water treatment facilities, they play a key role in filtration and distribution, while in food and beverage processing, they maintain hygienic and consistent operational standards.

TYPES AND VARIETIES:

Control valves come in various types to meet industrial needs. Globe valves excel in precision throttling, while ball valves provide effective on/off control with low-pressure drops. Butterfly valves suit large pipelines due to their compact design, and diaphragm valves support hygienic processes. Angle valves handle high-flow scenarios, while advanced valves with positioners offer dynamic accuracy. Customizable materials and trims enable them to manage extreme conditions, making control valves indispensable in modern industries.

SEE THE MOST EASILY MAINTAINABLE VALVE EVER PRODUCED!

Selecting the right control valve for your application is our top priority! Complete the form below and our team will be happy to size and select the right product for your application!