Each one of our regulators is specifically engineered to fit your needs!

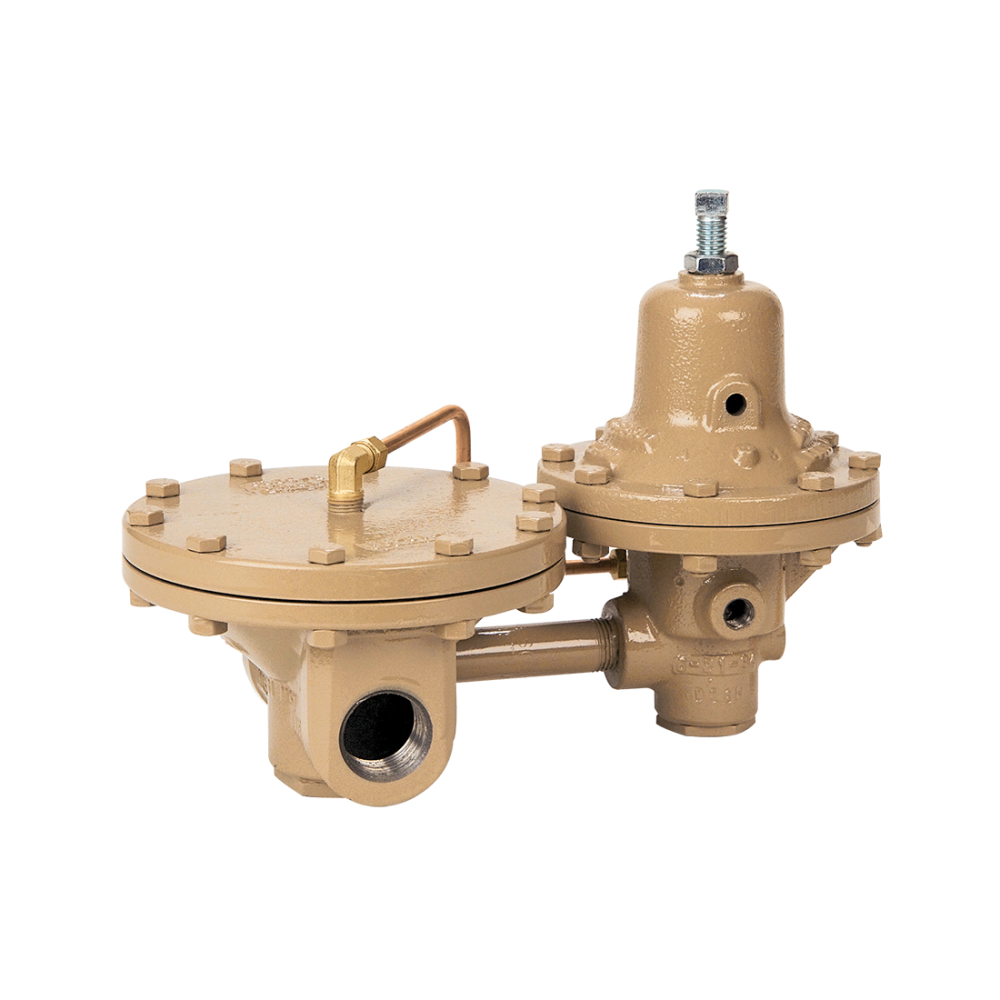

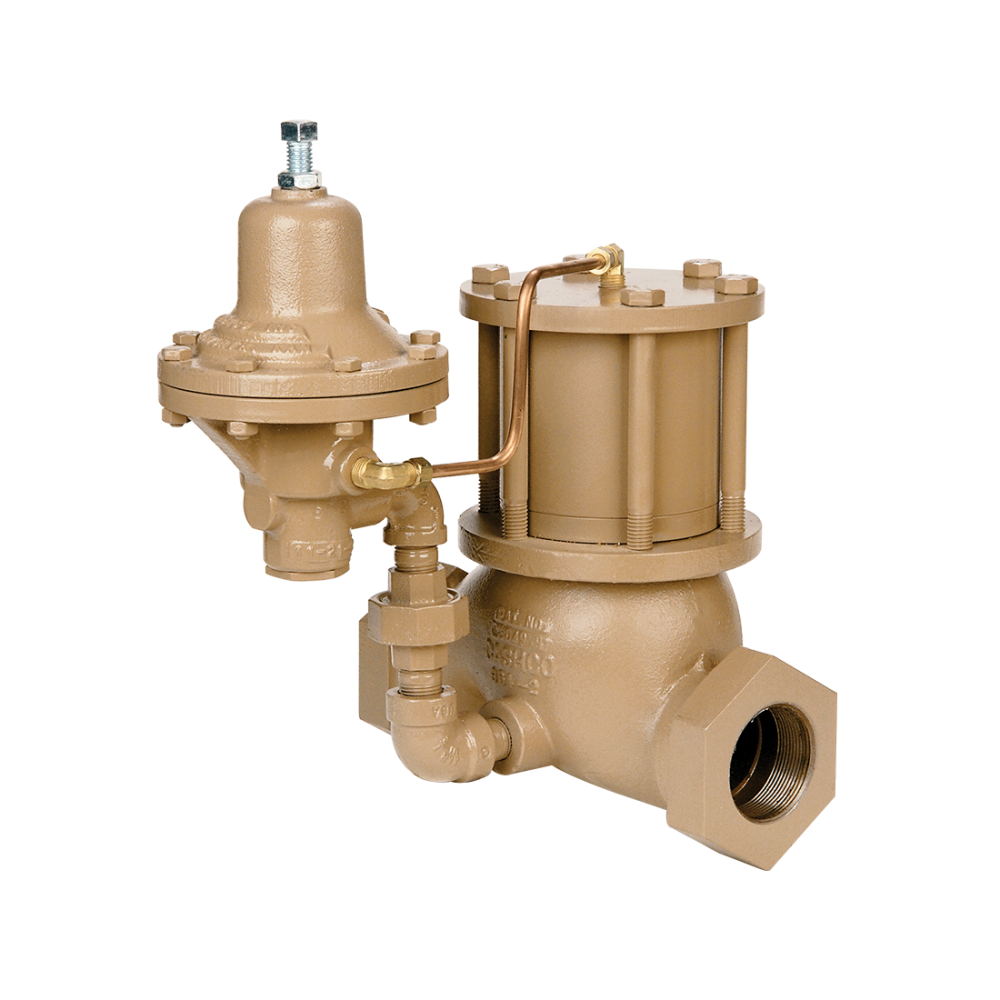

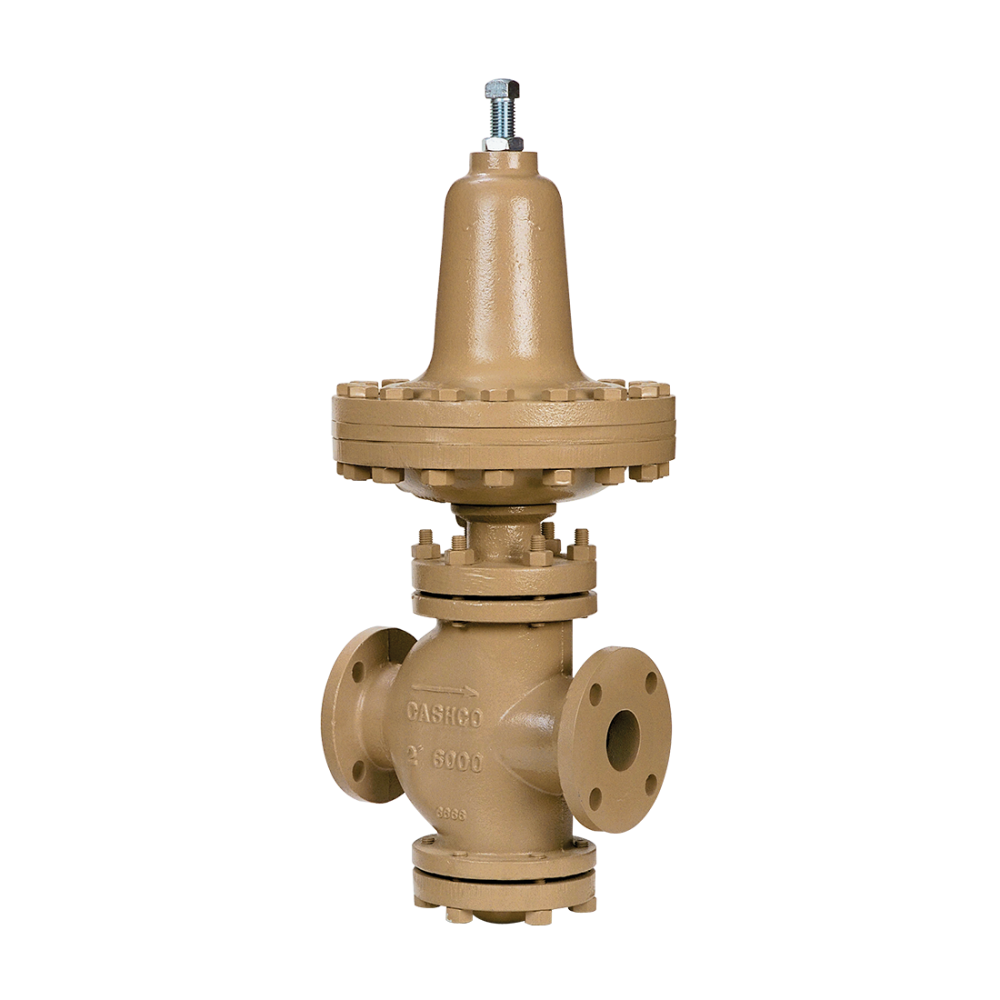

Our Top Selling Pressure Reducing Regulators

What is a pressure reducing regulator?

A pressure reducing regulator, often referred to simply as a pressure regulator, is a device used to control and reduce the pressure of a fluid in a system to a desired and safe level. Pressure reducing regulators play a crucial role in various industrial applications to ensure that the pressure within a system remains within acceptable parameters. Here are four different categories to help explain pressure reducing regulators:

FUNCTION AND PURPOSE:

Pressure reducing regulators are primarily designed to reduce the inlet pressure of a fluid to a specific, lower outlet pressure. This is essential in systems where high pressure could be damaging or unsafe, such as natural gas pipelines, pharmaceutical manufacturing processes, and industrial machinery. By reducing the pressure, these regulators help maintain system integrity, enhance safety, and optimize the operation of downstream components.

OPERATION:

Pressure regulators work through a simple yet effective mechanism. They consist of a diaphragm or a piston that responds to changes in pressure. When the inlet pressure exceeds the setpoint, the diaphragm or piston adjusts the valve to reduce the flow of the fluid, thus lowering the outlet pressure. Conversely, when the inlet pressure falls below the setpoint, the regulator allows more fluid to flow through, maintaining the desired outlet pressure. This dynamic control ensures a stable and consistent pressure level.

APPLICATIONS:

Pressure reducing regulators find applications in a wide range of industries. In the oil and gas sector, they are used to control the pressure of natural gas as it is transported from production sites to end-users. In residential settings, pressure regulators are employed in water distribution systems to maintain a safe and consistent water pressure for household use. They are also vital in manufacturing, where precise control of pressure is necessary for various processes, such as welding, cutting, and filling containers.

TYPES AND VARIETIES:

Pressure reducing regulators come in various types and designs to suit different applications. Common types include direct-acting regulators, pilot-operated regulators, and dome-loaded regulators. Direct-acting regulators are simple and cost-effective, suitable for low-flow applications. Pilot-operated regulators are more complex and suitable for high-flow applications, offering enhanced accuracy and control. Dome-loaded regulators use a gas-loaded dome to provide fine control and stability, making them suitable for critical applications, such as in the chemical and pharmaceutical industries.

SEE HOW A PRESSURE REDUCING REGULATOR WORKS!

Regulator Sizing Help!

To ensure acccurate sizing and model selection, follow the steps below and submit your process data using the online form, or downloadable PDF!

Step 1: Complete the Online Form or Download the PDF

You can enter your process data directly on this page using the form below, or download the editable PDF version to complete offline.

Step 2: Focus on Required Fields

Required fields are marked with a red asterisk (*). These are essential for proper regulator selection, including your media, normal operating pressures, temperature and flow rate.

Step 3: Include Minimum and Maximum Conditions

Even if optional, providing your minimum and maximum values gives us a better understanding of your full operating range for optimal performance.

Step 4: Confirm with Your Process Engineer

If you don’t have all the data, please reach out to your process engineer or the end user. Accurate information ensures the best-fit solution.

Step 5: Submit and Receive a Quotation

After submitting your form, our Inside Sales team will run a sizing report and provide you with a model recommendation, quotation, and lead time.

We’re here to support your process—every step of the way.

Want to complete it offline?

Download the editable PDF, fill it out at your convenience, and email it to sales@cashco.com.

Download Editable PDF